The Captain plunges bravely into the fibreglass dust storm to get the drum on this superbly reconfigured Bertram 25.

Most blokes toil away on tinnies and 15ft CrapCrafts before laying tools on their first big project, but — amazingly — this beaut Berty is Byron’s first boat! Fortunately, he had some help from one of his best buddies, Jack McKenzie of Finesse Marine.

AT A GLANCE

Boat: Bertram 25

Name: Odin

Owner: Byron Gobernatz

Occupation: Mining, maintenance supervisor

Lives: Mackay, Queensland

Builder buddy: Jack McKenzie

Tell us about the Berty, Byron.

She’s an ’86 model, called Odin. That’s the original name. They don’t call these old girls the bulldozers of the sea for nothing. They’re wide and stable at rest — perfect for our waters off Mackay.

What’s she built for?

We live on the doorstep of the Great Barrier Reef and love exploring the white sandy bays and taking trips to the outer reef. We spearfish, love crayfish and don’t mind handlining yellowfin if they’re on the chew.

Where did you get her from and what condition was she in?

It was a four-day road trip to Melbourne to pick her up. Most of her life had been spent on a marina and she was your typical neglected 30-year-old boat. One of the inboard engines had seized, the drive legs had corrosion holes through them, many fittings were rusted on and 30 years of grime had built up in the bilge.

Angle grinder alert! Tell us about the rebuild.

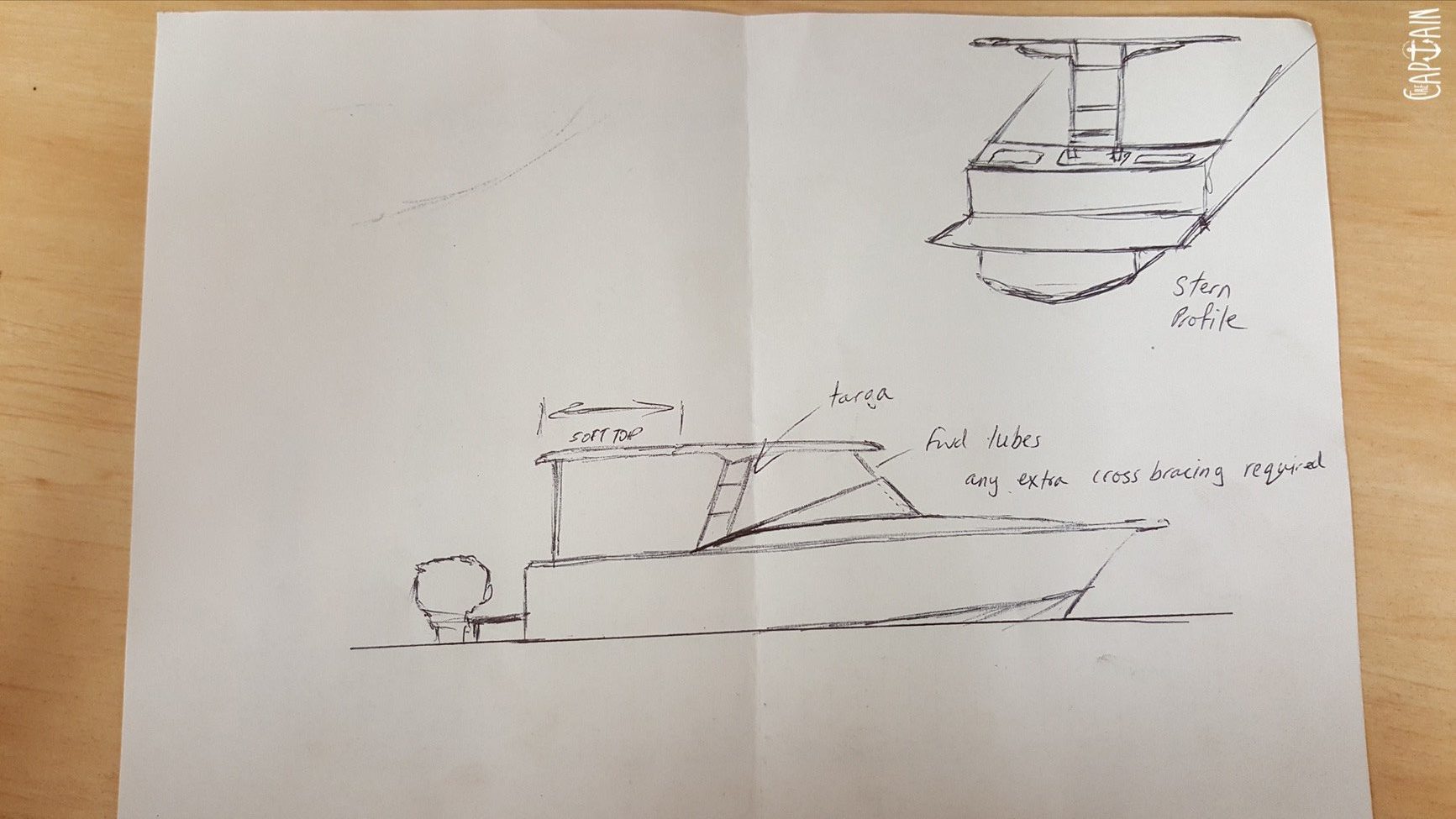

We stripped her back to a bare shell, modified the transom with a pod extension and did a complete refit. We put in new fuel and water tanks, plus a newly fabricated alloy canopy frame and a composite hardtop.

And the itchy stuff?

Odin is a full composite construction using Thermo-Lite and high-density foam. Everything was hand-laid by Jack and I using vinyl resin for the tanks and epoxy resins for the extension and fairing. We also used poly resin for general construction. Each resin had a certain purpose.

Does Jack have any good glassing tips?

Plan and prepare the job. Get your tools ready, cut the glass to size and have resin and buckets ready. Don’t tackle more than you can handle and wear the right safety gear.

And the paint finish?

She was fully faired in an epoxy system, then polyurethane-primed and finished in Awlgrip topcoat. Jack treats every step like he’s prepping for a topcoat. He’s a fussy bloke.

Just the guy you need. We love the express configuration with the L-shaped saloon. Describe the boat in five words

Fast, heavy, comfortable, excessive, beast.

Now she’s on the water, how does she ride?

Odin eats up the slop for breakfast and skims across the glass at 45 knots pushed by a pair of Suzuki DF300s running 16 x 18.5-inch propellers. Her cruise speed is 30–32 knots.

Hit us with some boat specs, Byron.

She’s gone from 25ft to 27ft in length with a 3.1m beam and 3499kg when empty. She holds 800L of fuel and deadrise is around the familiar Ray Hunt mark of 22 degrees.

Correct weight, eh? What’s bolted on?

A Simrad NSS16 Evo3 screen, Simrad autopilot, through-hull transducer, 3D structure scan, Zipwake trim tabs, JL Audio system, custom-built switch panel, Hydrive steering kit, 130L Isotherm fridge, 10L hotwater system, REDARC solar system, EVA Tread for the flooring, Lonestar winch and a Transtyle trailer.

Holy freckle! What did the missus say about that?

Fortunately, she’s the adventurous type. She was cool, well, apart from those itchy nights in bed!

How long did your masterpiece take — and how much folding stuff?

It took 18 months and cost about $130K. But she’s everything I wanted in a boat. She looks great, goes fast and does all the things I love on the water.

What do you wish you knew before starting such a big project?

Even with Jack’s advice, I definitely underestimated how bloody long it would take and how labour-intensive the painting process would be. There’s 500 hours in the painting and fairing alone!

It’s handy having a qualified boat builder as a mate, yeah?

Jack started in fairing and spraypainting, so finish is really important to him. He also brought his big-boat experience to Odin. There’s no flowcoat and the trimming is high quality, as is the stainless. Paul Selby from Black Marlin Towers built the hardtop frame. It’s faultless and completes the whole design.

What was Jack’s best tip?

He encouraged me to have a plan and we rarely deviated from that. Jack did all the calculations for weight redistribution, including the hull extension. Everything was spot-on. There were no afterthoughts.

We better give Jack a plug, eh? How do we get hold of him to pick his brains?

Jack works at Finesse Marine in Mackay, Queensland. His contact number is 0420 711 173. He’s actually looking for staff, so if you’re qualified in construction, fairing or painting and looking for a sea change in a beautiful part of the world, give him a call. Love ya work, fellas (and Bec!). The Captain salutes you.

Recent Comments