The latest alloy artwork from AMM is built for sport fishing northern adventuring. It seems a shame to scratch that silky smooth duco, but what the hell, pass the Gold Bombers and drop the hammers.

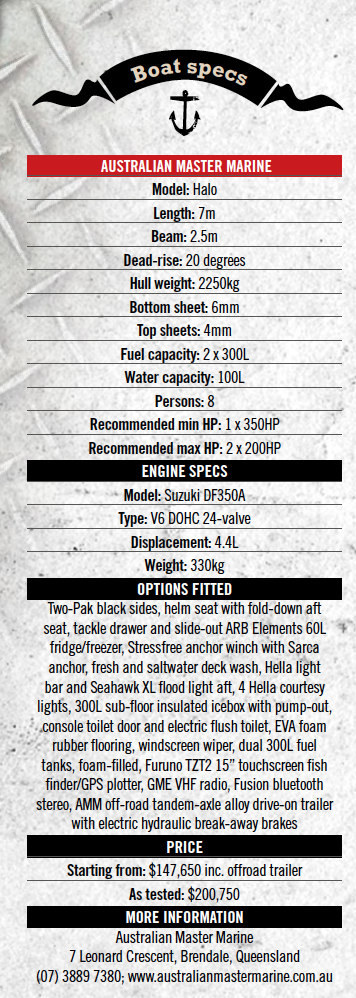

Boat-building brothers Barton and Matt Thomas recently invited The Captain’s crew aboard their latest creation, the 7000 Halo. They didn’t have to ask twice — the last AMM we stepped aboard was a pants-expanding 400HP Cape York dream machine. The Captain has fond memories of that rig from issue #6.

The Halo is a centre console with a centre-cab vibe. The DNA of the hull is shared with other AMM 7000 models — the Weekender and Tournament hardtops. Barton calls it a “well-proven shape”. The name “Halo” was a no-brainer considering the roof styling and configuration. The lid is super-light, weighing only 40kg. The minimalist construction uses 2.5mm alloy atop a 6mm curved glass windscreen. Barton assures us a couple of blokes could still hang off the back.

AMM boats have ramp presence and the Halo cuts a svelte shape in the low light creeping through the mangroves at Spinnaker Sound Marina. We’re on a morning mission to Moreton Island. Despite having no bow rail, the Halo passes the casting test — you can lean your shins up against it with your toes against the internal combing for a good foothold when that metre-long barra grabs hold of your Bomber.

“We wanted to keep the lines as clean as possible, so the bow rail was ditched and a handrail fitted flush with the coaming at the front,” Barton explains.

TOUGH TOURER

The Halo is designed for island hopping in northern waters or gamefishing operations. It’s got the range of a North Korean ballistic missile with twin 300L fuel tanks and 100L freshwater capacity.

Bulk storage is built in, including 6ft (1.8m) headroom in the console. There’s even a toilet and sink in the console, with ventilation ducts to ensure it stays mould- and stink-free after a tropical downpour. And it’s 100 per cent watertight. If you’ve ever toured up north in a trailer boat, you know everything gets pretty damp in the humidity, but Barton’s boys have done their darnedest to minimise the moisture. Even the stubby holders in the console drain first to the sink drain, then out the side.

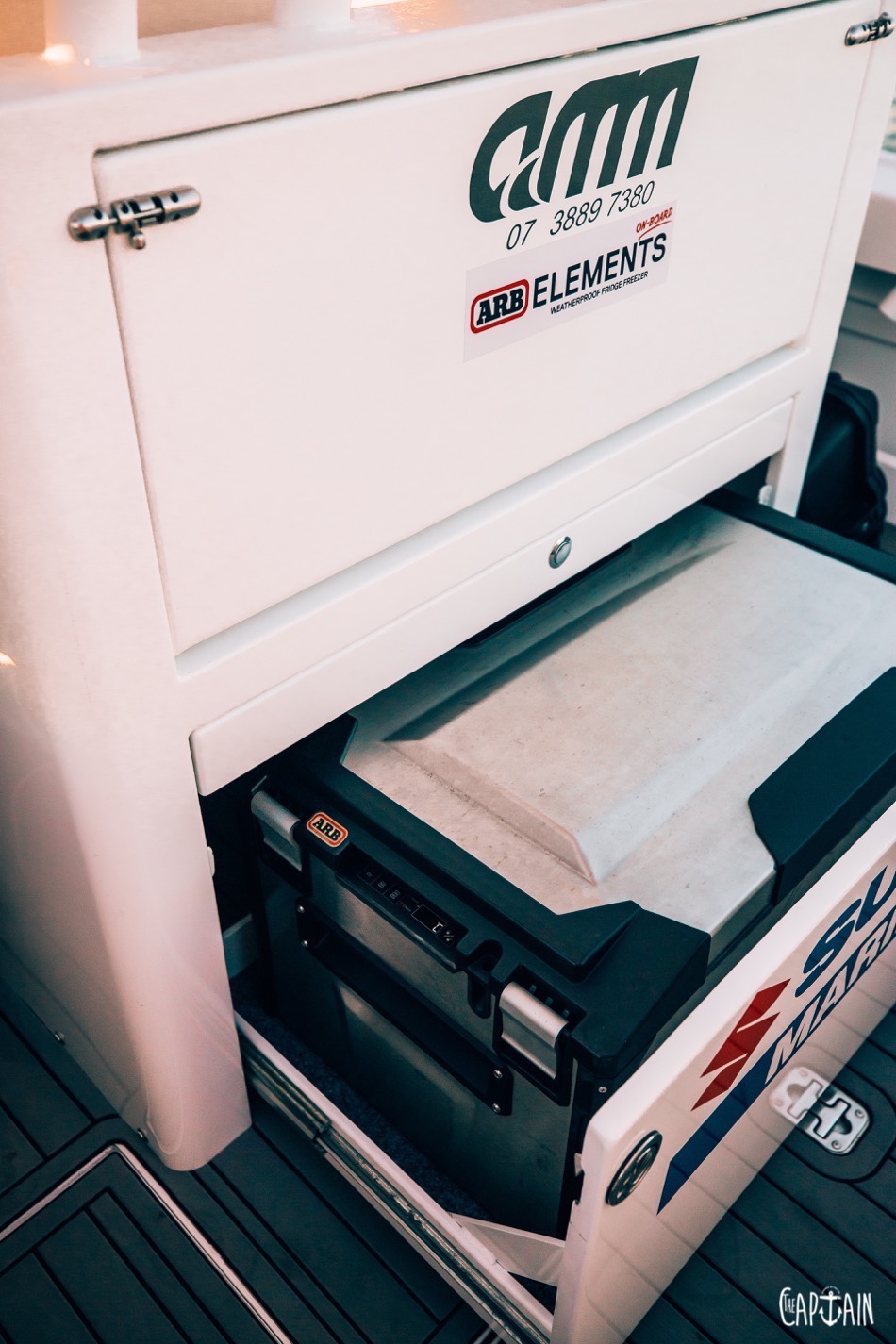

The boat is also a masterclass in refrigeration. Under the floor, between the helm seat and bait board, rests a 300L icebox shrouded in 50mm of insulation foam and fibreglass. It’s fitted with a pump-out and macerator system, and is an awesome bit of kit for keeping fish fresh in hotter climes. A slide-out ARB Elements fridge sits in the helm seat. The fridge lid (and the underfloor icebox lid) sits on gas struts. It’s a nice ergonomic feature, eliminating the need to rest the lid on your head while you’re searching for the last can of XXXX.

Also configured into the helm seat is a slide-out tackle drawer. It’s wide and shallow so you can access all your favourite barra lures in a split second, rather than untangling them from your Dad’s ancient Plano tackle box. Above the tackle draw sits a drop-down, aft-facing dickey seat — perfect for sitting and observing the spread, or maybe even laying out a BBQ cooktop and meal. It’s another nice touring touch.

SMOOTH AS, BRO’

AMM boats have a reputation as some of the best-finished tinnies on the water. It’s evident in the paintwork and the finish in the bollards, cleats, rails and rod holders. Barton has no qualms about using filler on his boats, either, even though some boat makers mutter that it’s a taboo practice. He reckons the right fillers in the right hands can work wonders. “We spend hours and hours grinding the welds back and apply just a finger-wipe of epoxy fairing compound, then sand that back out to the top of the weld. It takes out the little imperfections for a really nice, clean finish.”

The Halo features a deluxe paint job — two-pack white marine paint for the internal and side decks, and two-pack satin black on the sides. “Being black, it’s going to stand out, so we fair the sides to get it nice and straight. On this boat there’s less than 1mm of fairing to give it a smooth-as-silk finish.”

TORQUE CONVERTER

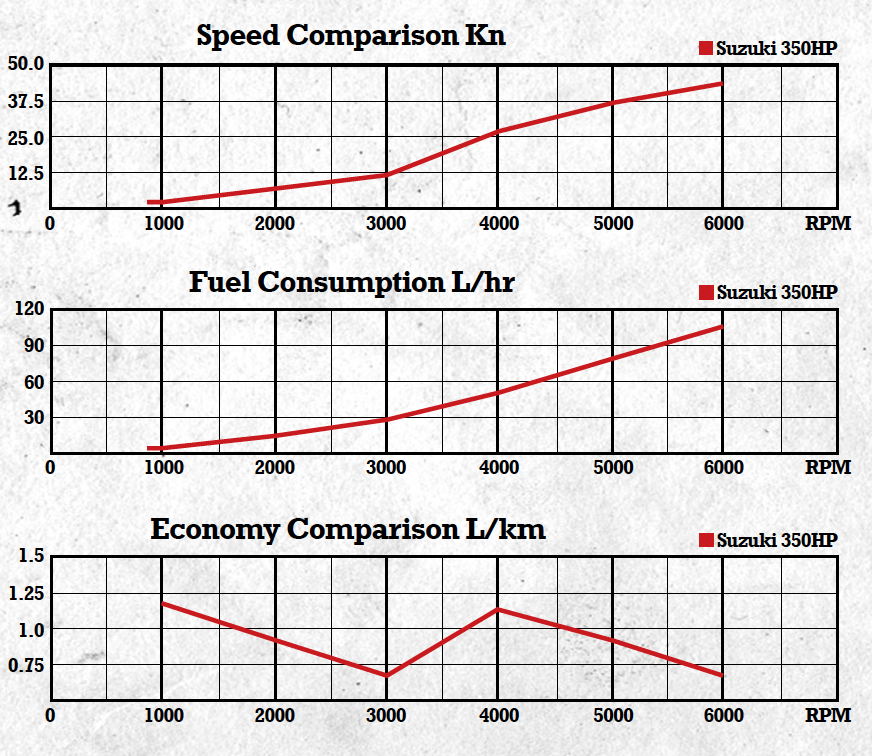

The Halo is running a single V6 4.4L Suzuki 350 with dual prop. It’s a sensible option for those who want max power without the weight of twins. That makes sense for a mid-weighted console. Barton has driven plenty of boats and reckons the Halo is, “a perfectly balanced boat with a low planing speed.” This is not only efficient — it also means you can navigate bars and river bends at a safe pace without dragging the skeg behind you.

Barton doesn’t throw praise around wildly, but he dotes on the big Suzi. “It’s the best Suzuki outboard I’ve ever driven and does everything it’s meant to and more,” he says.

“You can drive the wheels off the thing at 44 knots or just poke along the river. The counter-rotating props are amazing. There’s no torque twist in the hull and you don’t need trim tabs to balance the boat. When you lift that engine up and put it in reverse, my God! It’s sure got some thrust going backwards.”

SWEET RIDE

Unfortunately, we didn’t make it to Cape York for our test run, but we’re sure the AMM bros will lend us the keys and a trailer next time round. Instead, we ran up past Bribie Island to the northern tip of Moreton Island to do some wave chasing. Then it was back down to the Tangalooma Wrecks for a dive, swim and fish.

Our test day was piss-calm — not ideal for rough-water wave riding. Nonetheless, the 6mm foam-filled hull resting on 20 degrees of dead-rise proved smooth and quiet without a hint of clang or slap. The Captain’s verdict? The Halo goes as good as it looks. If you’re comfortable rubbing your new $200k rig up against a rock bar or putting a few stone chips in the paintwork, then hook ’er up to the Cruiser, grab the boys, fill up the tanks with XXXX and head north. We couldn’t think of a better rig to do it in.

ABOUT AMM

Australian Master Marine, aka AMM, has been crafting plate aluminium boats in its Brisbane compound for the past 25 years. Master builder and owner Barton Thomas began bending aluminium as an apprentice at Lloyd Ships in the 1990s.

He then worked for various companies, refining his craft on everything from superyachts to 10ft tinnies. He even did a couple of years on fibreglass boats on the Sunshine Coast, but couldn’t resist the urge of cold-pressed metal. “I chose aluminium and stuck with it,” Barton says. “I love the fact you can weld it up and clean it up. It’s a beautiful material to work with.”

With his brother, Matt, he owns and operates AMM out of Brendale, 30 minutes north of Brisbane. His job is more than just selling boats. “It’s not just a boat — it’s the experience and process of building one. Once our customers get the boat they dreamed of, they become part of the AMM family” he says. “A lot of AMM owners have their own businesses. They understand what it’s like to have a business and appreciate what we go through to build a boat for them.”

Barton reckons the most rewarding part of his job is, “designing and fabricating something new, then seeing the product work at the end of the day.” He estimates there are about 500 AMM vessels on the water today, distributed all around Australia, but mainly in the northern states.

THUMBS UP

– Masters of metalwork

– Clean lines

– Beautifully balanced boat

– Soft and smooth

– Cat-like handling

– Refrigeration options

– Bulk storage

– Comfy seats

– Gas struts on lids

– Plumbed stubby holders

THUMBS DOWN

– Heavy steering

– Smallish step to casting deck

– Roll out the green stuff – the motor is $43K, the trailer is $23K and the paintwork is $15K – that’s before you’ve even stepped on the boat.

MORE INFORMATION: www.australianmastermarine.com.au

Recent Comments