The Captain’s crew takes two steps forward and 445 steps backward on the project boat rebuild.

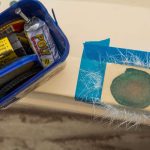

Nathan Laidlaw, master craftsman at Boat Box, seen below chopping like an ’80s rock star, gave The Captain’s crew a crash course in filling and fairing holes left over from rod holders and rigging. Here are his 6 steps to a smooth finish:

PART 1: THE HOLE

A. FAIR THE HOLE

Fair the hole around the edges with a grinder, creating exposed glass – this gives the new resin something to soak into. Place backing tape on the opposite side. Mask around the area you want to work, avoiding unnecessary mess.

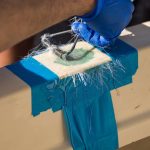

B. FILL THE HOLE

Wet small sections of chopped glass with polyester resin and apply it piece by piece, using different sized pieces to create an overlap. Dab it in with a brush then roll it out with a consolidator to remove any air bubbles. Don’t be afraid to go too high – you can always sand it back.

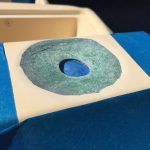

C. TRIM YOUR WORKING AREA

When the glass work is tacky, use a Stanley knife to cut around the fill area and peel the surrounding glass out. This will save time rubbing back useless glass, focusing only on the repair area.

D. FLATTEN THE FILLED AREA

When the glass repair is firm, sand back with some 40-grit sandpaper, always using a block, working in a circular motion, clockwise, then counterclockwise. Then fill with a light coat of fine filler and rub back with 80-grit sandpaper, working through to 240- grit on a block. The experts say: “the less filler (or bog) you use the better”. Too often it’s used as the main filling component, which creates hassles as it expands at a different rate to the surrounding glass, creating noticeable edges in your new two-pack finish.

E. ITCHING’S A BITCH

Fibreglass fibres are nasty, so use disposable gloves, a mask and goggles – and cover exposed skin to avoid serious itch. When cleaning up, Acetone is the way to go, but don’t get that stuff on your skin, either.

F. SMALLER HOLE REPAIRS

Hit smaller screw holes with a countersink drill bit to expand the hole face area, then fill with Gorilla Hair product (or equivalent). Essentially it’s resin with fine fibre in it. These repair products come with a small clear plastic sheet, which is laid over the repair. Just smooth it out, let it dry then rub it back, fine-fill and rub back again for the perfect finish. Now she’s ready for paint.

PART 2: THE TRUTH

To the guy who sold us the Haines Hunter 445F (yeah you, the guy who never returns our phone calls): I hope the new house you’re building – partly funded by the sale of the 445F is sturdier than the rotted-out boat you sold us. Your sad tale of selling your (“refurbished”) dreamboat to keep the missus happy was touching. I was completely convinced as I forked out nine grand for your shitty ship.

Your boat repairer was also convincing. “I would never lay a new floor over bad timber” were his words. But funnily, he couldn’t recall whether you were actually a customer. I’m no pro, but when the new floor came up, it was pretty obvious the bulkheads and stringers were rooted. The exposed wet timber was a dead giveaway.

Those canny captains proclaiming, “Buyer beware!” couldn’t be more right. But we’ve got an even better piece of advice. It’s called, “Don’t be an arse when selling shit”. Thankfully, there are a few champions out there. On hearing our plight, a more-than-handy custom boat builder offered his services to fit new stringers and floor to the Nub Tub. What could we say? Naturally, we hitched up the trailer and headed south with a few cold ones packed in the back of the Landy for emergencies. To be continued…

WHAT THE PROS SAY

How to avoid buying a rotten classic, from those who know:

Adam Davey, Davey Marine, boat fit-out and electronic specialist, new and used boat dealer

“A Bunning’s trade account doesn’t make you a boatrestoration expert. Ideally, the work on your potential dream rig has been done by a shipwright, boat builder or qualified marine tradesman – with documents and photos to support the work. It’s not to say that a diligent tradie with YouTube access can’t do a good job restoring a boat; it’s just that they don’t have a name or reputation to lose in the marine game.”

Erick Hyland, WhitePointer Marine, builder WhitePointer 263 and SuperHornet

“Many boats from 30 or 40 years ago were built in the production era – they pumped the bloody things out. You only need to look under the floor and see the rough edges, exposed timber and uneven lay-ups. They were also built with inferior materials and tools compared to today’s standards. If you want a good boat that lives on the water and not in your garage, buy a new one. Even then you can’t be sure. Have a look at what boats the commercial guys use if you want a boat that’s built well from day one.”

Ben Toseland, Toseland Marine, builder Bass Strait 6m Ocean Pro

“Just because there are pretty photos of freshly glassed stringers, it doesn’t mean the build is any good. I follow the Old School Haines Hunter Facebook site and I often see the wrong construction materials being used. I also see weight in the wrong places. There’s an optimum hull weight to get the best on-water performance – and some of these boats are going well over it. An on-water test may help indicate what’s going on below the floor.”

Recent Comments