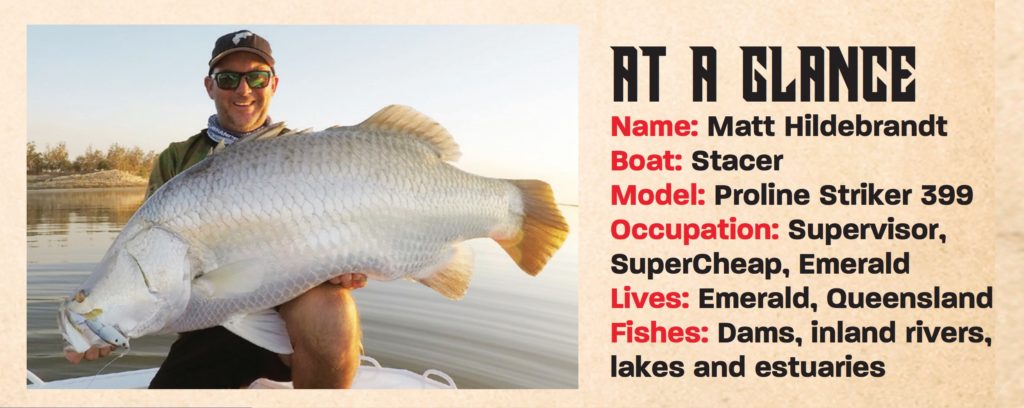

Matty Hildebrandt used all his car-painting smarts and product knowledge to give his 4m Stacer a Riviera-like finish — better, in fact.

G’day Matt. We haven’t had any punters from Emerald in The Captain. How’s the fishing up there?

The best thing about living in central Queensland is the endless fresh and saltwater options — all within three to four hours’ drive from Emerald. Most of the rivers have wild southern saratoga and our local dam is stocked with some XOS barra. It’s an isolated slice of heaven.

Sounds like a great place to get away from the toilet roll-buying freaks, mate. Tell us about the rig.

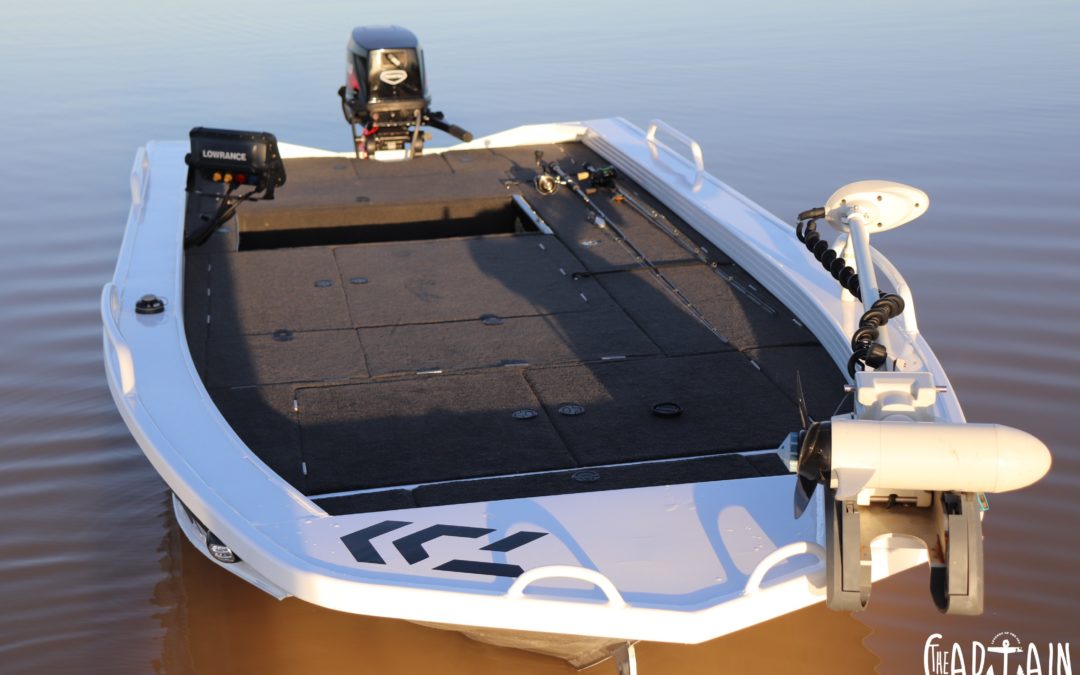

It’s a Stacer Proline Striker 399. I bought it new from Northside Marine in 2018. On the options list, I ticked the wide gunwales and transducer mount from the factory. I’ve always liked the Stacer Prolines. They’re well-built boats and after I fished out of a mate’s boat, I had to have one of my own. The redesigned hull was a big plus for me. The sharper chines and relaxed keel line makes it a faster and smoother hull than previous models. There’s a reason it’s one of the most popular 4m hulls on the market.

What rig did you have before this one?

A 4.1m Sea Jay vee-nose punt. I customised it with a side console, front and rear decks and lockers. I really needed a smoother, more stable hull. I also wanted to go back to a tiller steer to create more usable fishing space and storage.

OK, tell us about the new tinny.

I had a blank canvas, without any dodgy previous owners or bad modifications to deal with, and I was ready to modify. I wanted an awesome creek and dam boat, but it had to come in under $10K. I researched plenty of other small rigs. I set out with a list of things I wanted and sketched out some designs.

Hit us with the fine detail.

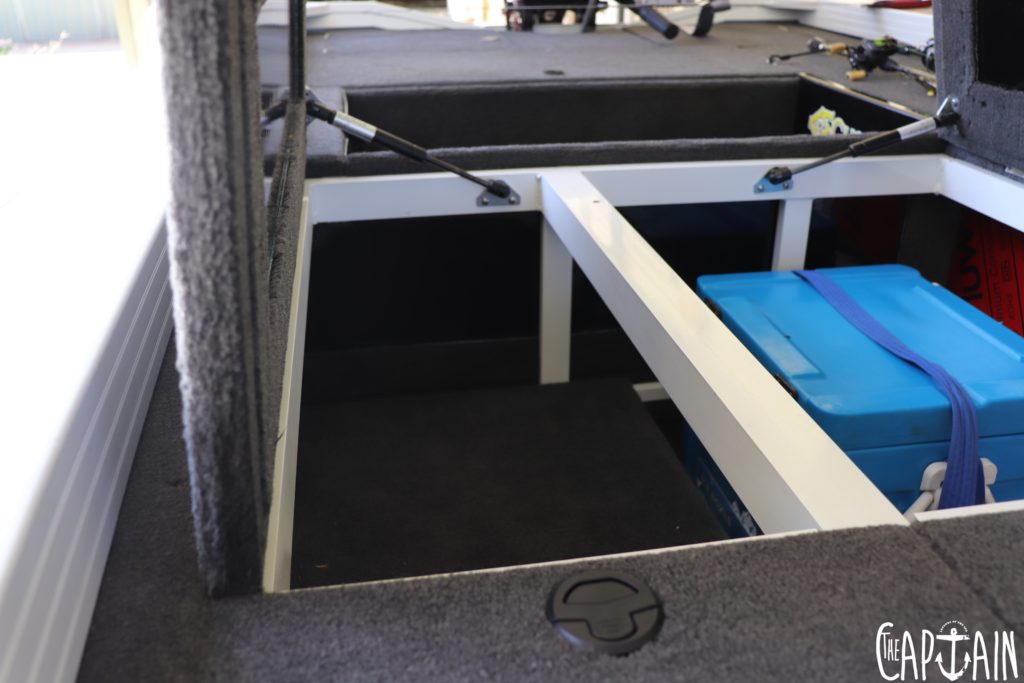

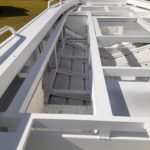

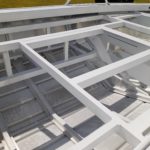

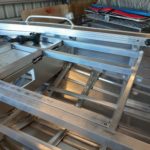

The main frame is built out of 1.6mm 50mm x 50mm box section. I needed purchase for the hatches when closed. The rest of the frame is made from 50mm x 25mm with a bit of 40mm x 20mm here and there.

Did you get any help?

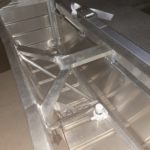

A good mate helped with the welding. He’s a qualified boilermaker. We spent three days going over the designs, making everything functional while keeping the weight down. We stayed with the original seats for bracing and flotation, as well as a 50L plumbed live well in the cavity. We cut and laid out the top section of framework and tacked it into place using a pulse MIG. Then we removed the top section to make a jig so it wouldn’t distort when we were finishing off the welds. Once that was done, we placed the frame back in and continued cutting and welding all the supports.

We can practically smell those burning welding rods, Matt. Tell us more.

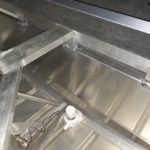

We raised the rear deck to be level with the front. Then we gusseted the transom to the rear casting deck for added strength. The battery frames are 50mm x 50mm right-angle alloy. The house battery is in the middle of the rear casting deck and the electric battery is under the footwell — it’s an AGM slimline to save space. There’s also 47L Icekool icebox under the deck.

What about the finishes? You work in a auto shop, so we’re tipping that helped.

Good materials help, but it’s all about the prep work. First, I used a metal etching gel to dull and etch the boat before giving it a light sanding. Then I washed the boat, blew it out with compressed air and wiped it clean with Norglass Norclean plus. Then came three coats of Norglass Shipshape 2k polyurethane primer. I let that dry for three days before sanding. Then I laid on another coat of Shipshape primer followed by two days of drying — and even more sanding. For the base coats I used Norglass Northane gloss 2k polyurethane.

What about the colour scheme?

She’s black outside and white inside. I kept it simple to minimise masking time. The 2k polyurethane product gives an excellent gloss appearance that can withstand the elements.

What about the decks?

The deck is made from 12mm formply sheets. It’s cheap, strong and if treated right will last forever. I used Bote-Cote two-part epoxy with a black pigment on all surfaces, including the edges. I also painted the hatch undersides in Norglass Northane gloss for a clean black finish. I used charcoal-coloured premium non-loop hook-less carpet. It’s 7mm thick — the same stuff they use in Skeeter boats — glued with Purbond adhesive and screwed down with stainless hinges and ring pulls from Whitworths.

Love it. What’s she rolling on?

I found a bargain trailer in Noosa on Gumtree and bought it sight-unseen for $500. It was ridgy didge except for rusted bearings, which were an easy fix. I work in an auto shop, after all. I replaced the 10-inch wheels with 14-inch polished alloys and added 175/60 R14 tyres for more ground clearance and looks. I threw on some new skids and rollers, rewired and painted it in silver gal. Then I headed west to Northside to pick up the new rig.

Let’s talk electronics.

I was budget-conscious, so landed on a Lowrance HDS Carbon 9 and a Xi5 MotorGuide. They link together for accurate positioning. It’s perfect for what I do — at the perfect price for my budget.

What about the donk? The manufacturer transom rating is 30HP, but you’ve got plans for a 40HP out the back?

Yeah, I plan to. For now, I picked up a late-model 30HP two-stroke Tohatsu with electric start. It was a bit knocked around so I touched it up with Norglass black then added fresh decals and gave it a full service. It’s mounted a little higher for better performance. I also fitted a custom foil that makes a world of difference. With two people on board, 25L of fuel and gear she pulls 43km/h (23 knots). I had the hull surveyed for the 40HP outboard — so it’s all, er, above board for the new donk.

Now she’s finished, are you happy with it?

Absolutely. She came in at $9K and took 300–400 hours and 12 months to build. She’s a very stable and comfortable platform to fish from, and a pretty dry ride, even in sloppy conditions. Most importantly, it suits my style of fishing, which is 100 per cent lure fishing.

Speaking of fishing, how’s that going?

So far, I’ve caught a dozen barra over a metre plus a personal best of a 120cm model.

Well done mate, best 4m tinny we’ve seen. Any final tips for the DIY tinny rebuilders out there?

Do your research, have a plan and keep the weight down. If you’re casting, spend the time to get the higher, level decks.

REBUILDS AHOY!

If you’ve finished your sweet rebuild and want to see it in the rum-stained pages of The Captain, send an email to thecaptain@mobydickcontent.com. Every published yarn receives a service kit* from Stuart and Mel Buckingham at Outboard Spares, *Or similar-value item. That’s just in case you’re running quads on a Somali pirate boat. Note that using non-genuine parts on warrantied engines may affect your warranty. Be sure to check.

SAND & WEED ARE TRYING TO KILL YOUR OUTBOARD

Words by Stuart Buckingham

Our rivers, bays, seas and estuaries all consist of various environments — from sand, rock and weed to gravel, mud and so on. Fish love these habitats, but our outboards don’t. Here’s why.

Culprits: Sand, Rock and Gravel

Damage: Sand and gravel are experts at finding their way into your cooling galleries and blocking them up. Rocks will rearrange your propeller blades — and most likely your gearbox, too. I recall an unhappy customer contacting me who had broken down while on holiday at Mallacoota, in Victoria. His engine-overheat alarm was constantly going off, even though the water pump and thermostat assembly had been recently replaced. I removed the gearbox and found the water pump was fine. However, when I removed the thermostat cover, I found the entire thermostat housing and surrounding galleries were chock-full of sand and gravel — and it had set like concrete. The bewildered owner couldn’t believe what we found, but later acknowledged it probably happened when he was trying to get the boat off the trailer at a shallow sandy ramp on his first day.

Culprits: Weed

Damage: Won’t necessarily block the cooling galleries on the outboard, but it can destroy water pumps and impellers. Ribbon weed (or similar seaweed) can be a problem in both shallow and deep waters, where it floats in thick clumps. It can block the intake on the gearbox housing that feeds the water pump — restricting the water flow and causing the water pump housing to have insufficient lubrication for the impeller. The end result is a damaged impeller and/or complete water pump.

In your quest to catch a mighty metre-long barra like Matt Hildebrandt, be aware of the danger zones — banks and shallow channels, weed patches, floating debris and ramps at low tide. If you’re a safety Sam, follow the channel markers, trim your outboard up in shallow water and keep an eye out for any changes in the environment. Oh, and keep your outboard well serviced, just in case. Carrying spare parts on board can also help get you out of a pickle. Pickleweed, that is. For more tips on used boats and outboards, check out www.outboardspares.com.au

- DCIM103GOPROG0221833.JPG

Recent Comments